Axial Fan Blade Failure

This paper includes the affects on the performance of axial fan due to the failure of different parts.

Axial fan blade failure. The depth and length of the cracks and the rapid increase in vibration from the fan speed apparently from the fan blade flexing at the crack s during rotation led to the conclusion that at least one blade was on the way to catastrophic failure. Flow induced vibrations and failure of axial fan blades in electric generators axial ventilation by use of axial fans was the most common cooling concept for hydropower generators in sweden during the 50 70 s when the main part of the swedish hydropower plants where built. Causes of inadequate airflow to the fan include a backwards installed or running impeller improper blade angle setting missing cut off an impeller not centred with inlet collars slow fan speed dirty or clogged inlet improper running clearance or improper inlet cone to wheel fit. Both blades were replaced with care to maintain the balance of the entire assembly and then.

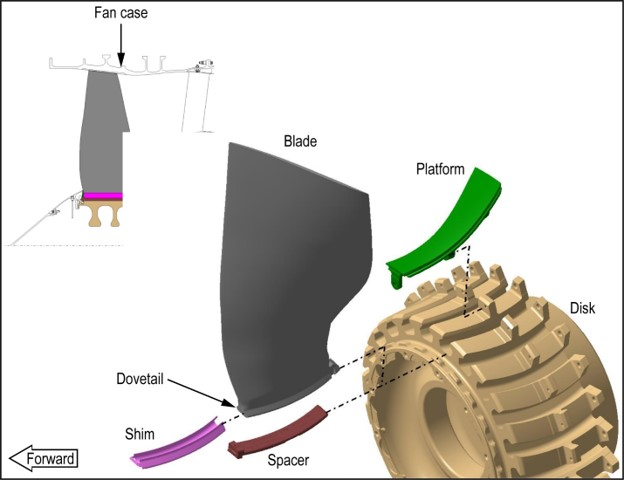

Axial fans are divided into three groups propeller tube axial and vane axial whereas centrifugal fan are classified as airfoil blade radial fans forward curved fans and backward inclined curved fan. The forced draft fan fdf blade in a 300 mw coal fired power plant that experienced catastrophic failure has been investigated. E authors concluded that the blade crack was due to fatigue situations in resonance state and the. Visual inspection metallographic analysis chemical composition and hardness test were carried out to find the cause of the failure.

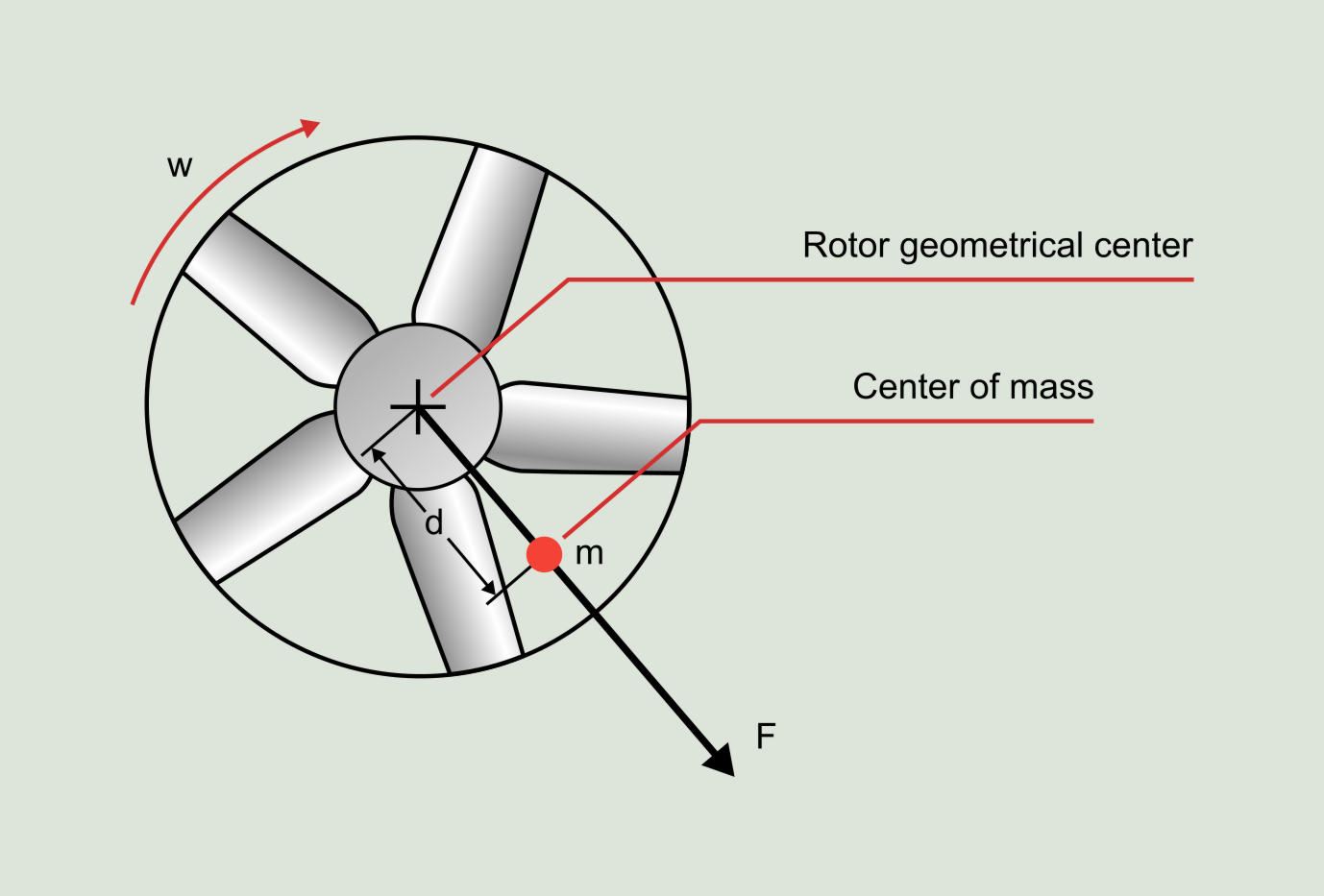

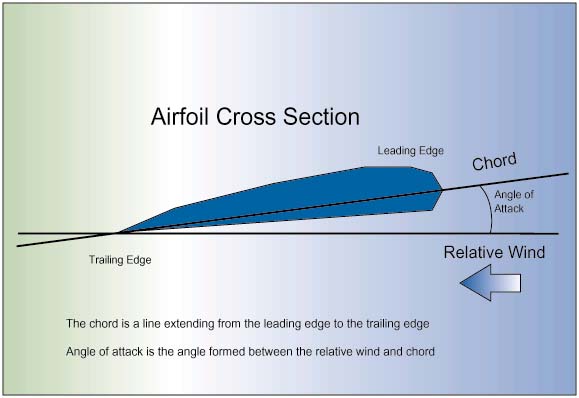

There were two main locations of the blade damage namely damage at. An axial fan is a type of fan that causes gas to flow through it in an axial direction parallel to the shaft about which the blades rotate. Axial flow fan impellers will also be subject to centrifugal forces and thus the various elements will be stressed. The fan is designed to produce a pressure difference and hence force to cause a flow through the fan factors which determine the performance of the fan include the number and shape of the blades.

The fdf blade has been run for 5 years and before its failure the fdf experienced high vibration 14 mm s. As in most cases the blades are cantilevered and only supported at the end adjacent to the hub fluctuating stresses are more important. Wtw bill cory in fans and ventilation 2005. 7 8 stressing of axial impellers 7 8 1 introduction.

An axial fan blade can be considered as cantilever beam on which air pressure and centrifugal force are applied blade failure due to different forces during its operation is analysed by fixing its one end at hub by v block as shown in fig. The forced draft fan is an axial flow fan horizontally in front of the boiler and the fan is single stage.