Average Cfm For Air Tools

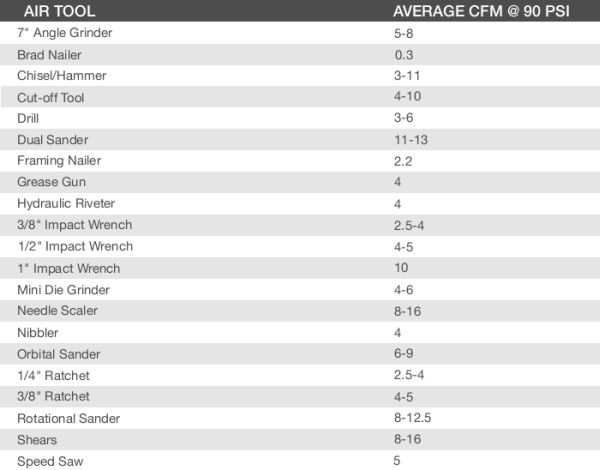

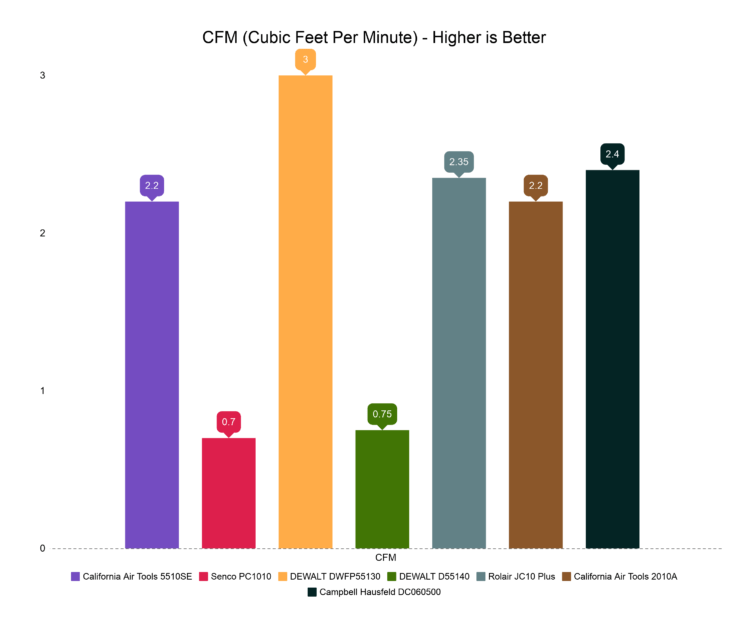

Reference this chart to determine what continuous cfm rating is required of your air compressor.

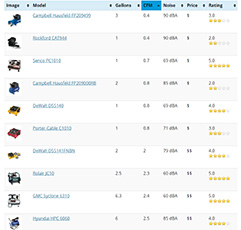

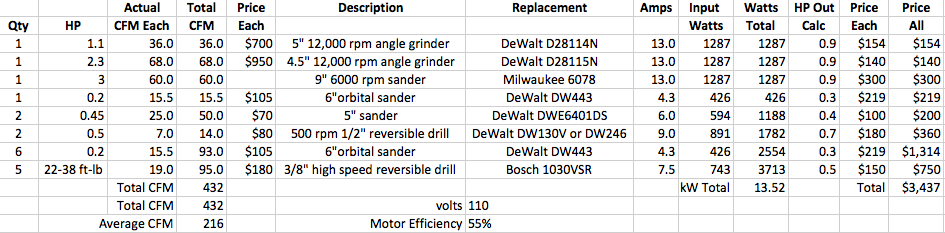

Average cfm for air tools. The majority of air tools operate in the 90 to 100 psi range and most air compressors from the smallest to the largest can easily produce this much pressure. Table pneumatic air tool cfm 90 psi pneumatic air tool cfm 90 psi angle disc grinder 7 6 cfm grease caulking gun 4 cfm air drill 1 2 or 3 8 4 cfm hydraulic riveter 4 cfm. This article defines air flow rate or cubic feet per minute cfm as the term is used to describe building air conditioners heating systems or building air movement rates. Use the chart below to determine your average cfm requirements per tool or check with the manufacturer.

Whether it s an impact gun grinder or breaker there are various ranges of air consumption each of these tools use. Air hoist 1000 lb. As a general reference here are some popular tools and their average cfm requirements. We ve also included 6 tips for choosing an air compressor the average cfm at load 100 duty cycle the suggested air compressor cfm and our recommended rotary screw air compressor based on your cfm needs.

We ve put together a handy air tool consumption chart to help give you an idea of how many cfm you need to run your air tools. The chart below includes some common air tools and their average cfm measurements. Step 2 once all the air requirements have been determined total the cfm needed for the air compressor. Here are some of the most common air tools and their average cfm requirements.

Air flow rate data. Air tools are often rated as average cfm average cfm is typically based on a 25 duty cycle 15 seconds out of a min. Air tool equipment average free air consumption cfm air bushing. The real deciding factor in selecting the proper size air compressor is the cfm that it can produce.

In the example below we are sizing the compressor for a typical auto body shop. We include examples of manufacturer s air flow rate or cfm data for hvac equipment like air conditioners and furnaces. A common question we get revolves around how much air a particular tool uses. Keep in mind that air tools are rated on a 25 duty cycle in use for 15 seconds out of every 60 seconds so for continuous use tools such as grinders you may want to multiple the cfm number by 4.

Please note this is only a guide.